Catlin Mattheis – CEO and Founder of Fracsun

Solar energy is way past proof-of-concept projects; instead, the main industry efforts are financial and practical as we reach into global scale. Investors and companies interested in solar energy are not just motivated by environmental concerns, but also by the return on their investment. In the current tough economic climate, every advantage counts, and having access to accurate and actionable data can be a key to success. Today’s article is about energy losses that come from dirt on solar system panels.

Catlin Mattheis, the CEO and Founder of Fracsun, identified a gaping opportunity for improving the returns of large-scale commercial projects with better cleaning and maintenance schedules. But the story of dirty panels begins with dirty data.

Fracsun, based in San Luis Obispo, California, is an exciting start up that specializes in on-site soiling loss measurement, assessing and predicting the cost of suboptimal performance in order to mitigate it effectively.

“We eliminate uncertainty and enable your team to confidently monitor and manage soiling loss with ease,” Catlin says. So what is soiling loss?

Soiling loss refers to the decrease in efficiency of solar panels due to dirt and other contaminants that accumulate on their surface. Like a dirty window, soiling can reduce the amount of sunlight that reaches the solar cells, reducing the amount of electricity that the panels can produce. Measuring and mitigating soiling loss is important for ensuring that solar panels are operating at their maximum potential.

Cleaning the panels on the roof of your home is trivially easy. But imagine owning thousands of solar panels spread across hundreds of acres in a remote part of the desert where you have to truck water in. Workers have to work at night when the panels are cooler and energy output is near zero. Cleaning the whole installation is expensive, so you don’t clean unless you have to, but maybe you can get away with a partial cleaning. Thus, the question is: when to clean and which panels to clean?

A need revealed through a long solar career

Catlin has been working in solar one way or another for more than 15 years. He started with REC Solar as an intern in 2007 where he received a crash course in both residential and commercial solar. “They seeded a lot of people into the industry,” he notes gratefully. As a mechanical engineer, he involved himself in design work and installations to better learn the solar industry.

After a brief foray into plasma physics and fusion energy, Catlin returned to solar once again with REC Solar. It was there, around 2011, that he started kicking around the idea of how to measure and mitigate soiling loss. “At that time, no one was really thinking about it,” he says. “Everyone was focused on lower-hanging fruit.”

With the help of two co-founders, an electrical engineer and “a physics guy with an MBA,” Fracsun was born. “We knew that the industry would eventually come around,” Catlin says. “Now everyone’s asking about soiling loss so we start with the data. How do you measure how dirty something is?”

The hardware side of soling loss management

The IEC defines various ways of measuring soiling loss. Catlin explains that Fracsun uses a method whereby “we measure a short circuit current on two reference devices, cells six inches square. One of those cells is automatically cleaned every day. Conceptually, it’s as simple as can be. It’s the implementation that’s the rub.”

That’s particularly true of retrofits, which account for many of Fracsun’s customers. For these projects, the company employs self-powered, integrated smart systems that don’t require running any cabling into large installations. For the customers who enlist Fracsun before installing solar, the company also utilizes freestanding units to assess potential build sites for soiling.

Fracsun’s product in the field.

The data side of soiling loss management

“Getting the hardware portion right is critical, but it’s the data that’s the ultimate goal. We take the raw data and run it through financial algorithms on daily loss values,” Catlin explains.

“Getting the hardware portion right is critical, but it’s the data that’s the ultimate goal. We take the raw data and run it through financial algorithms on daily loss values,” Catlin explains.

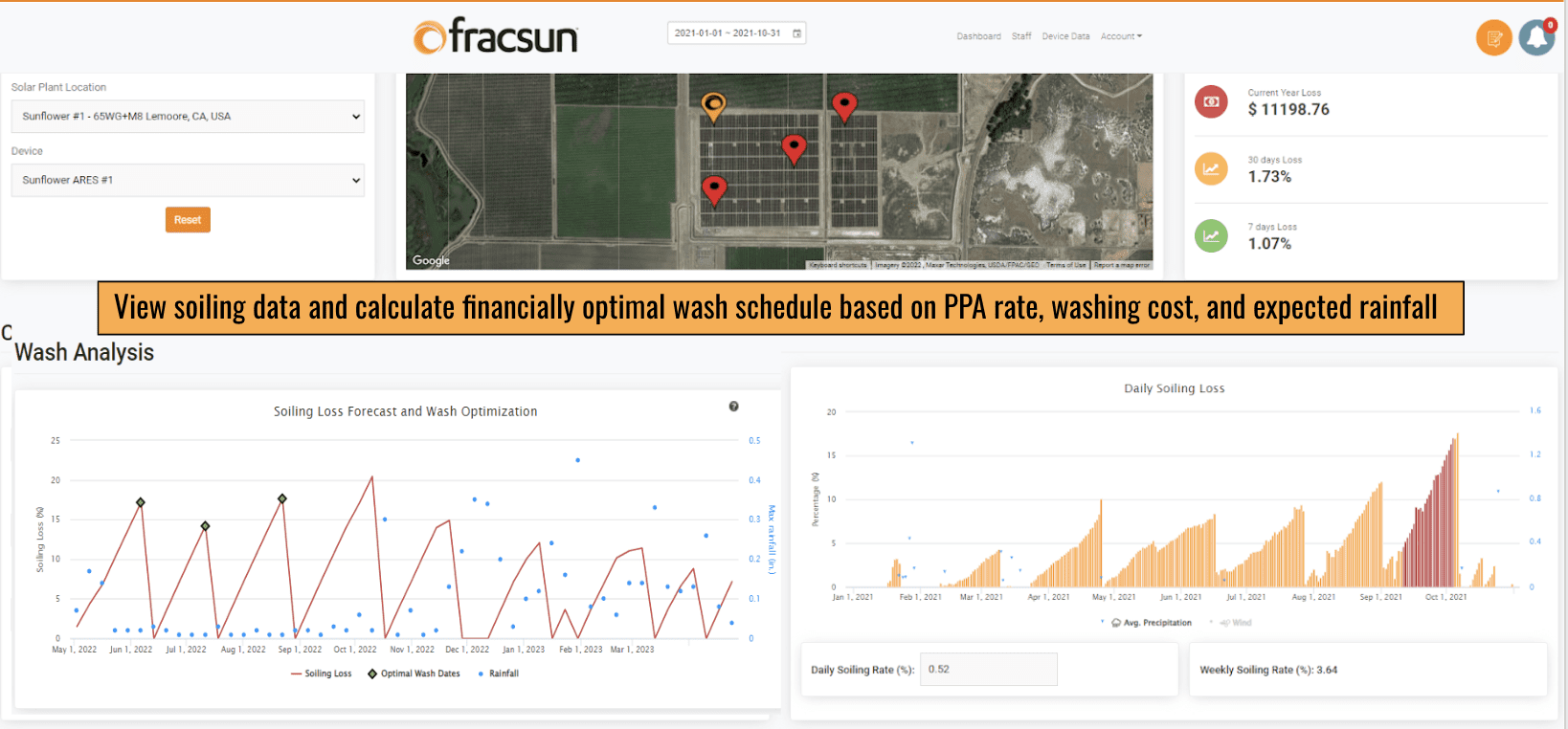

“We built a tool where you can upload your energy output information for your solar plant, and you enter in key metrics like cost-to-wash and the value of your energy. From there, we do a one-year soiling loss forecast at the site using measured data and past trends, including average rainfall and other local factors.”

This site-specific prediction model is critical to assessing soiling loss. “We look at every possible scenario to see which is most financially optimal and report that to the user,” Catlin says.

A look at the data you can expect for calculating soiling rates.

The localized economic value of cleaning

Cleaning panels to improve output makes complete sense. But just how much sense is the big question. “Most of our customers know there is some economic benefit to cleaning,” Catlin says.

It’s clearly beneficial, he notes, when the improved production outweighs the cost of cleaning—and to know that, you need to base a cleaning scheduling on a financial model that is rigorously quantifiable and provable.

The tricky part is that there is no one-size-fits-all, rule-of-thumb model for assessing financial viability. Catlin compares customers on the east coast (where pollen is a greater soiling problem) and in the Southwest, where dust and wildfire ash cause greater issues. And that’s speaking generally; two sites across the street from each other can vary depending on wind patterns, traffic, and development, and then there are seasonal variances to consider too.

The more site-specific data we can acquire the better and there’s a surprising difference between two adjacent fields. A small hill, a couple of buildings, or a band of trees can really change how soil gets deposited. In agriculture communities, when you harvest and when you clean is very important.

“There’s economic value to cleaning. I just need a tool to quantify that value,” Catlin says. And that’s what Fracsun’s assessment service provides. “On a large site, the savings could represent maybe a six-percent annual improvement on performance. At net-zero cost, too, because you’re calculating to make sure those cleaning costs are paying for themselves.” That may not sound like much, but for a utility scale system that could mean thousands of dollars per day in avoidable losses.

Soiling loss measurement as a tool for project development

There’s definite value in assessing existing solar plants for soiling loss. The real groundbreaking idea in Fracsun’s model is assessing proposed solar sites for project development—as early in the process as selecting a build site.

“We offer this data as a service,” Catlin says. Thanks to licensing agreements that allow Fracsun to share data anonymously, they can anticipate what expected sunlight and soiling loss will be within a certain radius or block of land.

This data analysis is invaluable to the assessment of large commercial builds. It better informs financial models up front and better defines cost/benefit analyses for investors.

“For big installations, this can move the needle significantly,” Catlin says. “You can plan for this on the front end. It’s a really useful tool we’ve built out.”

De-risking business in a high-interest environment

Years of low-interest rates directly benefited the solar and commercial real estate industries. Solar in particular has spent the bulk of its existence in a low interest rate environment. But that changed in 2022.

Products like Fracsun’s soiling loss mitigation become infinitely more valuable when companies see real margin compression. Smaller differences become critical to protecting investments.

“Often we bring up the idea of de-risking a project up front,” Catlin says. “The idea being, if you can de-risk a portion of a project, then the cost of capital should go down. A lot of O&M budgets are decided way up front, way out ahead of a project having a site chosen. If there is an unknown, soiling management and mitigation is the single biggest cost item in an O&M budget.”

“…if you can de-risk a portion of a project, then the cost of capital should go down. A lot of O&M budgets are decided way up front, way out ahead of a project having a site chosen. If there is an unknown, soiling management and mitigation is the single biggest cost item in an O&M budget.”

The conversation with financiers improves when you can approach them with a specified O&M budget that includes the biggest cost driver, cleaning, already dialed in up front with actionable data that shows how much the site will (or won’t) require soiling mitigation.

Regardless of the budget, a rigorous analysis removes uncertainty from the proposal and builds confidence for investors.

A better way to drive value

Cleaning and maintaining solar installations is a simple, sensical proposition. Fracsun maximizes that process to drive value for large-scale projects at any stage of development.

Quality insight into soiling loss is what the solar industry needs. “The vast majority of people using data to figure out when to clean are doing so using a lot of spreadsheets and old-school methods,” Catlin says. “Financial models are underpinned by some pretty garbage inputs. The industry is coming around, though.”